Advanced Polycarbonate Windows Engineered & Manufactured in the USA

At Five Star Fabricating, we offer polycarbonate windows that excel in both durability and protection. Featuring Fusionite™, our exclusive coatings deliver unmatched scratch resistance, longevity, and performance under the most extreme conditions. We are the only company capable of manufacturing complex shapes with advanced coatings, making our products the top choice for automotive, racing, and industrial sectors.

Our high-performance polycarbonate windows are engineered to provide superior impact resistance, outlasting traditional glass and even outperforming competitors like Gorilla Glass in durability and protection.

Uncompromising Safety Standards

Safety is at the core of everything we do. Our polycarbonate windows comply with OSHA and other industry safety regulations, ensuring enhanced protection across high-performance vehicles, industrial machinery, and commercial applications. With advanced coatings, our windows offer exceptional safety by preventing scratches, chips, and damage, making them ideal for critical-use scenarios where protection matters most.

Proven Performance Trusted by Industry Leaders

Top names in the automotive and industrial sectors, like Rivian, Tesla, and Zinger, trust Five Star Fabricating for polycarbonate windows that offer durability and reliability. Explore how our products meet and exceed the demands of these industry pioneers by reading our case studies and customer testimonials.

Why Choose Our Polycarbonate Windows?

- Scratch-Resistant Coating: Our proprietary Fusionite™ coatings protect against scratches, damage, and weathering, ensuring a longer lifespan.

- Custom Prototypes Available: Get a custom solution designed specifically for your needs, delivered within two weeks.

- Safety Compliance: Fully compliant with OSHA and other safety regulations, providing security in critical industries.

- Durability and Longevity: Our polycarbonate windows are engineered to withstand the most challenging environments, outlasting traditional glass options.

- Superior to Competitors: Offering greater impact resistance than Gorilla Glass, our windows are built for high-demand industries.

Applications and Industries

Our polycarbonate windows are perfect for various demanding applications, providing exceptional durability and optical clarity. Key industries include:

- High-Performance Vehicles: Trusted by leaders in the racing world, such as Zinger, for withstanding extreme conditions with Taber abrasion results of less than 2% haze.

- Industrial Equipment: Critical for safety applications in forestry and construction, providing durable, impact-resistant solutions.

- Aerospace: Engineered for aircraft canopies and cockpit windows, offering superior weatherability and long-term durability in harsh environments.

Leverage Prototypes for Better Sales

Our sales process, historically driven by personalized outreach, is now supported by digital assets like prototypes and case studies, making it easier than ever to discover why Five Star Fabricating is the industry leader. Request a free sample or prototype and experience our unparalleled quality firsthand.

OUR VALUE-ADDED PROCESSES

Substrate Enhancement

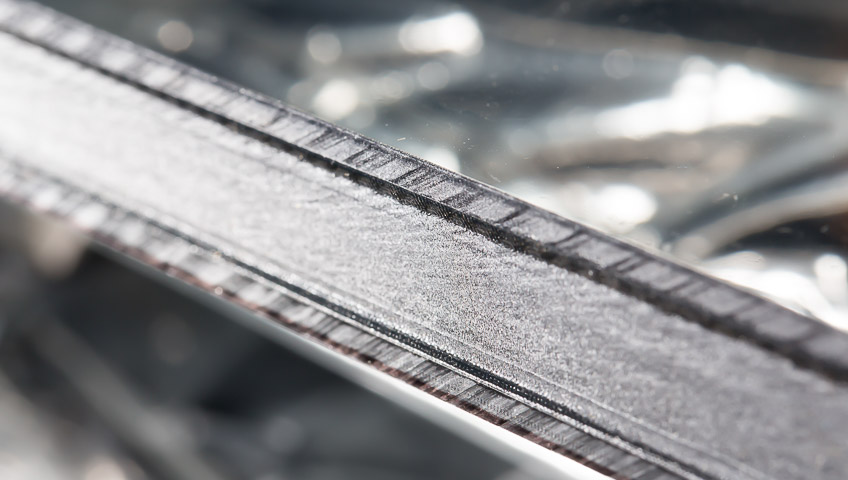

LAMINATING

BULLET-RESISTANT MULTILAYER WINDOWS

Our laminated windows are made by sandwiching one or more layer of polyvinyl butyral (PVB) between pieces of polycarbonate, then curing the materials with varying degrees of heat and pressure. This PVB layer is what allows the window to absorb energy during an impact.

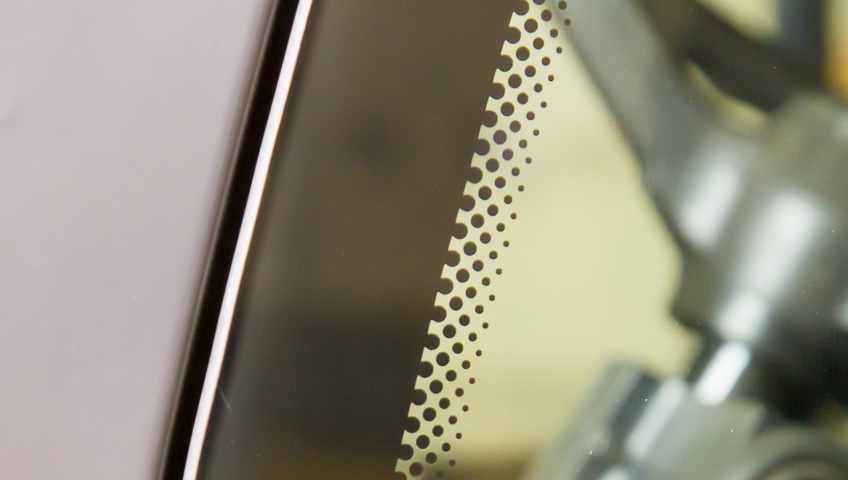

HARD COATING

APPLICATION-SPECIFIC OPTICAL COATINGS

We apply high abrasion, scratch & wear resistant coatings, anti-fog coatings, anti-static coatings, anti-glare coatings, anti-weatherable coatings, anti-reflective coatings, anti-fingerprint coatings & chemical resistant coatings.

Window Fabricating

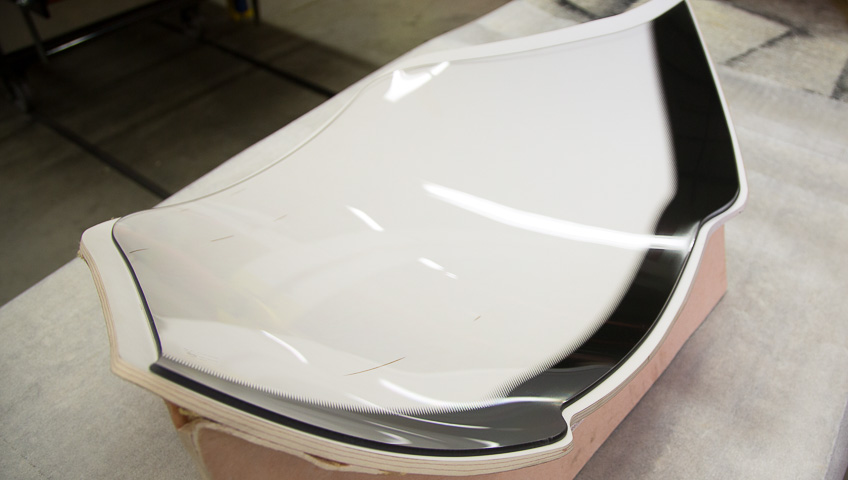

DRAPE FORMING

COMPLEX SHAPES WITH LITTLE DISTORTION

Our proprietary forming processes allows us to deliver products of all sizes and shapes, ranging from small helmet face shields to massive utility vehicle windshields. 5 on-site ovens allow us to meet high volume requirements within tight time frames.

Finishing Services

TESTING

GUARANTEED QUALITY

In our on-site testing laboratory, we employ various testing measures in accordance with ASTM International standards to test optical clarity, ink adhesion, long-term durability, chemical resistance and cosmetics.

Frequently Asked Questions

-

What are polycarbonate windows, and how do they differ from traditional glass windows?

- Polycarbonate windows are made from a durable, lightweight thermoplastic that is approximately 200 times stronger than glass. They offer superior impact resistance and are much lighter, making them ideal for applications that require both durability and reduced weight.

-

What are the key benefits of using polycarbonate windows in industrial applications?

- Polycarbonate windows are highly resistant to impact, chemicals, and extreme weather, making them ideal for harsh industrial environments. Their lightweight nature also allows for easier installation and handling compared to glass.

-

What coating options are available for enhanced performance?

- We offer coatings such as anti-fog, anti-scratch, UV-resistant, and anti-glare treatments to enhance the performance and longevity of our polycarbonate windows.

-

What makes Five Star's polycarbonate windows unique?

- Our polycarbonate windows are enhanced with Fusionite™ coatings, offering superior scratch resistance, impact protection, and weather durability, making them stand out from traditional options like Gorilla Glass.

-

Can I request a custom prototype?

- Yes, we offer custom prototypes tailored to your project specifications, typically delivered within two weeks after an initial consultation and CAD file submission.

-

How do your coatings enhance performance?

- Our Fusionite™ coatings offer exceptional performance enhancements, such as improved scratch resistance, UV protection, anti-fog, and anti-glare properties. These coatings significantly extend the longevity of polycarbonate windows, even in the most challenging environments like automotive, aerospace, and motorsports.

-

What industries use your polycarbonate windows?

- We serve automotive, racing, heavy equipment, and aerospace sectors, among other applications providing safety and durability where it's needed most.

-

How do I start the ordering process for a custom solution?

- Contact us to begin the process, which involves an initial consultation, signing an NDA, and submitting CAD files. We’ll guide you through design and prototype production.